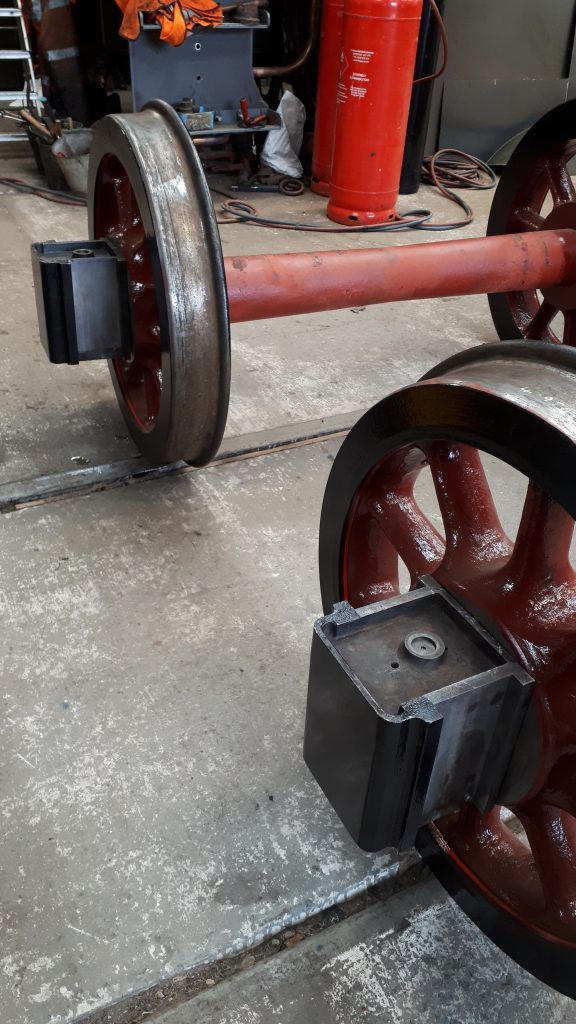

The wheels for Wootton Hall‘s tender have arrived in the shed ready for the new bearings to be scraped in. We are now in the process of procuring some lubricating pads although it seems that there is quite a lead time for these items.

The wheels for Wootton Hall‘s tender have arrived in the shed ready for the new bearings to be scraped in. We are now in the process of procuring some lubricating pads although it seems that there is quite a lead time for these items.

More items have appeared from the forge at Kirkham this week. Keith has been drilling holes in the newly-arrived steel supports for the tender footplate floor.

More items have appeared from the forge at Kirkham this week. Keith has been drilling holes in the newly-arrived steel supports for the tender footplate floor.

They have now been fitted into position although some adjustment to their shape is necessary before final fitting.

They have now been fitted into position although some adjustment to their shape is necessary before final fitting.

Work continues on painting the inside of Fluff‘s frames and Howard has been attending to the axleboxes.

Work continues on painting the inside of Fluff‘s frames and Howard has been attending to the axleboxes.

A second-hand replacement manifold for Caliban was the centre of Alan’s attention last Wednesday. It seems that it has been some considerable time since the various components have been dismantled…

A second-hand replacement manifold for Caliban was the centre of Alan’s attention last Wednesday. It seems that it has been some considerable time since the various components have been dismantled…  The old adage says “give me a long enough lever and I will move the earth”….

The old adage says “give me a long enough lever and I will move the earth”….  … and so Alan attempted to put this into practice with a series of pipes added to the handle of his stilsons! Adrian, famed for his dismantling abilities, joined to finish off the job.

… and so Alan attempted to put this into practice with a series of pipes added to the handle of his stilsons! Adrian, famed for his dismantling abilities, joined to finish off the job.

Fred finished cleaning out the top well at the back of FR 20’s tender and Roger completed the rather extended task of removing the protective gaffer tape from FR 20’s spectacle glasses – we won’t be doing that again in a hurry!

Fred finished cleaning out the top well at the back of FR 20’s tender and Roger completed the rather extended task of removing the protective gaffer tape from FR 20’s spectacle glasses – we won’t be doing that again in a hurry!

The tender tank is almost ready for painting and Phil Bell is also nearly ready to re-fit the first half of the brake rigging after cleaning and painting. John Dixon has again been underneath the tender and is seen giving the inside of the frames some paint.

The tender tank is almost ready for painting and Phil Bell is also nearly ready to re-fit the first half of the brake rigging after cleaning and painting. John Dixon has again been underneath the tender and is seen giving the inside of the frames some paint.

Finally, as forecast last week, Keith and Fred have been across to Embsay to give 5643 a wash-out prior to the operation of the Santa Specials there.

The front of FR 20’s tender has come back together now after a strip down for cleaning of the drag box and buffing gear. John Dixon is seen applying a coat of gloss black paint to the underside of the footplate floor last Wednesday before it was lifted back into position on Friday.

The front of FR 20’s tender has come back together now after a strip down for cleaning of the drag box and buffing gear. John Dixon is seen applying a coat of gloss black paint to the underside of the footplate floor last Wednesday before it was lifted back into position on Friday. Phil Bell has been back underneath the tender to give the inside of the steps a coat of black paint.

Phil Bell has been back underneath the tender to give the inside of the steps a coat of black paint. We let Phil out from the pit on Friday and he is seen here with a selection of the brake gear for painting.

We let Phil out from the pit on Friday and he is seen here with a selection of the brake gear for painting. Even the brake blocks are getting a coat of paint, from John Davis.

Even the brake blocks are getting a coat of paint, from John Davis. With the footplate floor back in place, Roger has been removing protective black tape from the spectacle glass windows.

With the footplate floor back in place, Roger has been removing protective black tape from the spectacle glass windows. John has re-installed the hand rail stanchions and is seen fitting one of the top hand rails.

John has re-installed the hand rail stanchions and is seen fitting one of the top hand rails. Fred spent all of Friday on top of the tender cleaning up the rear well with his trusty cup wire bush.

Fred spent all of Friday on top of the tender cleaning up the rear well with his trusty cup wire bush. There was more progress on Fluff with undercoat on one of the wheelsets and some gloss black paint from John Davis on the inside of the frames.

There was more progress on Fluff with undercoat on one of the wheelsets and some gloss black paint from John Davis on the inside of the frames. John Dixon has been working on FR 20’s tender footplate. It was originally slightly short of metal on the up-curve next to the coal hole, which had previously been overcome with the temporary expedient (20 years ago!) of being filled with fibreglass. Over time some of the fibreglass has broken up and so a proper job is now being undertaken this time around.

John Dixon has been working on FR 20’s tender footplate. It was originally slightly short of metal on the up-curve next to the coal hole, which had previously been overcome with the temporary expedient (20 years ago!) of being filled with fibreglass. Over time some of the fibreglass has broken up and so a proper job is now being undertaken this time around. Tim continues to prepare the tender tank and outside frames for painting whilst the brake rigging is also in the process of receiving a fresh coat of paint and Phil Bell is seen cleaning up one of the brake hangers.

Tim continues to prepare the tender tank and outside frames for painting whilst the brake rigging is also in the process of receiving a fresh coat of paint and Phil Bell is seen cleaning up one of the brake hangers. Fred has been cleaning up some of the brake pins.

Fred has been cleaning up some of the brake pins. Meanwhile Roger has been undertaking a long overdue clear out of the rear storage box on the tender, reaching into areas where no one has dared to explore for years!

Meanwhile Roger has been undertaking a long overdue clear out of the rear storage box on the tender, reaching into areas where no one has dared to explore for years! Fluff is slowly going back together and John Davis is pictured adjusting the cab foot pedal under the watchful gaze of Howard and John Dixon.

Fluff is slowly going back together and John Davis is pictured adjusting the cab foot pedal under the watchful gaze of Howard and John Dixon. Ade has again been attending to the axleboxes on Caliban.

Ade has again been attending to the axleboxes on Caliban. Keith has been shaping the injector delivery pipes for Wootton Hall.

Keith has been shaping the injector delivery pipes for Wootton Hall. John Dixon is seen here giving the matter some deep thought!

John Dixon is seen here giving the matter some deep thought! Underneath the tender, John Davis and Phil Bell have dismantled the right hand tender brake hangers for cleaning and painting and to give access to the frames. This has created further work for Fred who will no doubt be pleased to learn that a new batch of cup wire brushes has arrived!

Underneath the tender, John Davis and Phil Bell have dismantled the right hand tender brake hangers for cleaning and painting and to give access to the frames. This has created further work for Fred who will no doubt be pleased to learn that a new batch of cup wire brushes has arrived! Howard seems very happy at his work on Fluff.

Howard seems very happy at his work on Fluff. Work on the tender front drag box is progressing well with Roger applying a top coat of paint to the interior.

Work on the tender front drag box is progressing well with Roger applying a top coat of paint to the interior. John Dixon has been putting top coat black to the draw bar, buffing spring and also the drag box cover.

John Dixon has been putting top coat black to the draw bar, buffing spring and also the drag box cover. Fred has been cleaning up the tender handbrake (foreground) whilst John Davis (left) has been cleaning up axleboxes from Fluff.

Fred has been cleaning up the tender handbrake (foreground) whilst John Davis (left) has been cleaning up axleboxes from Fluff. Tim, Alan and Adrian gathered to jack up the rear of FR 20’s engine in order to release a spring. This is to be sent away to act as a pattern for a narrower set of springs that will be more appropriate to the engine’s weight, which has reduced to 25 tons rather than the 36 tons it had been as a saddletank.

Tim, Alan and Adrian gathered to jack up the rear of FR 20’s engine in order to release a spring. This is to be sent away to act as a pattern for a narrower set of springs that will be more appropriate to the engine’s weight, which has reduced to 25 tons rather than the 36 tons it had been as a saddletank. Keith has completed the metalwork for the new splashers for Wootton Hall, one of which is seen supporting one of its nameplates.

Keith has completed the metalwork for the new splashers for Wootton Hall, one of which is seen supporting one of its nameplates. Keith was able to purchase from the Worth Valley Railway a second-hand ejector elbow..

Keith was able to purchase from the Worth Valley Railway a second-hand ejector elbow.. .. and also second-hand firehole door mechanism for Wootton Hall.

.. and also second-hand firehole door mechanism for Wootton Hall. John Dixon has been creating a bar to be fitted on to the floor of the front tender drag box to support the buffing spring. He is seen here at work with the magnetic drill.

John Dixon has been creating a bar to be fitted on to the floor of the front tender drag box to support the buffing spring. He is seen here at work with the magnetic drill. Phil Bell, seen with John Davis, has continued his work below the tender frames which includes the dismantling of some of the brake rigging to allow access to the frames and for cleaning.

Phil Bell, seen with John Davis, has continued his work below the tender frames which includes the dismantling of some of the brake rigging to allow access to the frames and for cleaning. Tim has continued the task of sanding down the tender paintwork.

Tim has continued the task of sanding down the tender paintwork. Adrian and Alan have been engaged on the task of fitting new felt lubrication pads into Caliban‘s axleboxes.

Adrian and Alan have been engaged on the task of fitting new felt lubrication pads into Caliban‘s axleboxes. We haven’t seen many photographs of Howard lately so here is one of him filing down a metal insert into Fluff‘s new running board.

We haven’t seen many photographs of Howard lately so here is one of him filing down a metal insert into Fluff‘s new running board. John Davis has been cleaning up Fluff‘s springs.

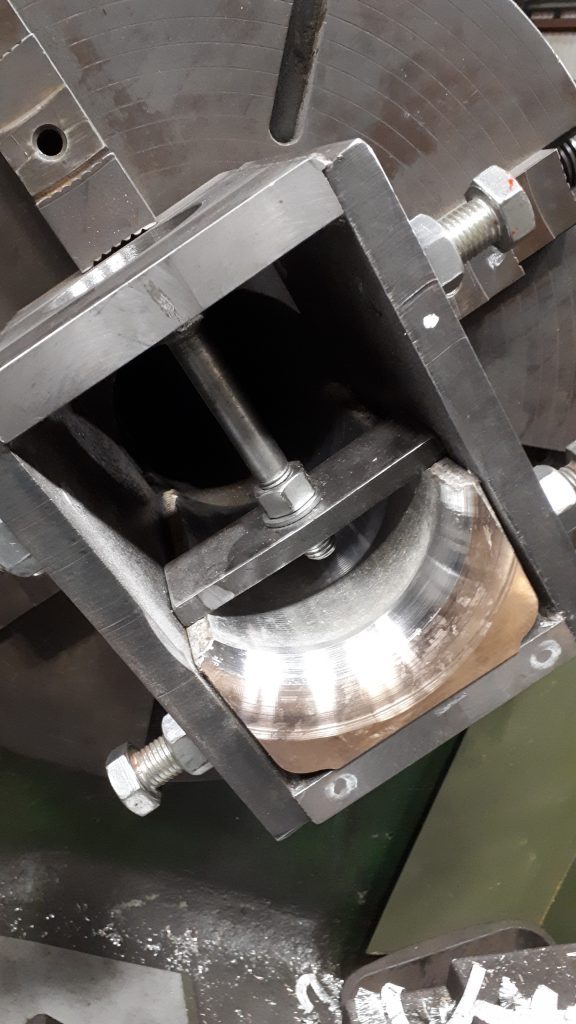

John Davis has been cleaning up Fluff‘s springs. Work has also continued this week on Wootton Hall‘s new splashers and the machining the newly white-metalled tender bearings, one of which is shown here.

Work has also continued this week on Wootton Hall‘s new splashers and the machining the newly white-metalled tender bearings, one of which is shown here. A second-hand CNC machine, the purchase cost being subscribed to by the FRT, arrived at Preston on Wednesday and has been positioned in the RSR workshop.

A second-hand CNC machine, the purchase cost being subscribed to by the FRT, arrived at Preston on Wednesday and has been positioned in the RSR workshop. Geoff Middleton was on hand to pipe in the last train.

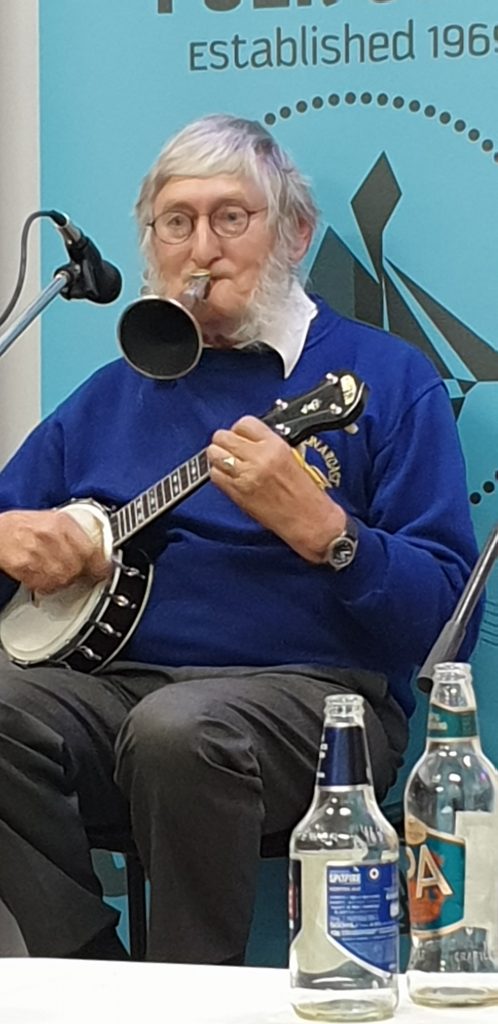

Geoff Middleton was on hand to pipe in the last train. Meanwhile brother Alan entertained as a one man band.

Meanwhile brother Alan entertained as a one man band. Over at Embsay, Cumbria made a successful return to traffic with the Sunday dining train (thanks to the Embsay loco group’s Facebook for the picture) while 5643 is lined up for a few repairs this week.

Over at Embsay, Cumbria made a successful return to traffic with the Sunday dining train (thanks to the Embsay loco group’s Facebook for the picture) while 5643 is lined up for a few repairs this week. First it was necessary to remove the curved fall plate, the bridging piece between the tender and the engine.

First it was necessary to remove the curved fall plate, the bridging piece between the tender and the engine. Once the tender floor plate had been removed, there was then the more difficult task of removing the thick plate directly above the drag box which could not be moved until both the draw bar pin and the buffing spring pin had been removed. The latter was found to be seized in the lower base plate and so it was time to call in Ade, who has “previous” in taking apart those things that don’t want to come apart! With assistance from Tim also, the pin was finally extracted late last Wednesday afternoon after many applications of jack, heat and a sledgehammer. Ade is seen here at work with the latter, watched by John Dixon, Keith Brewer and Neil Glover.

Once the tender floor plate had been removed, there was then the more difficult task of removing the thick plate directly above the drag box which could not be moved until both the draw bar pin and the buffing spring pin had been removed. The latter was found to be seized in the lower base plate and so it was time to call in Ade, who has “previous” in taking apart those things that don’t want to come apart! With assistance from Tim also, the pin was finally extracted late last Wednesday afternoon after many applications of jack, heat and a sledgehammer. Ade is seen here at work with the latter, watched by John Dixon, Keith Brewer and Neil Glover. Once two of the buffer guides and the buffers had been removed, Roger then assisted John last Friday in the task of cleaning up the drag box.

Once two of the buffer guides and the buffers had been removed, Roger then assisted John last Friday in the task of cleaning up the drag box. A coat of bright orange primer was then applied.

A coat of bright orange primer was then applied. Meanwhile Tim has been sanding down the one of the tender sides and Phil Bell has been cleaning the tender brake rigging.

Meanwhile Tim has been sanding down the one of the tender sides and Phil Bell has been cleaning the tender brake rigging. Fred has been busying himself cleaning the tender springs and hangers.

Fred has been busying himself cleaning the tender springs and hangers. Keith has been cutting out new sheet metal for Fluff‘s running board.

Keith has been cutting out new sheet metal for Fluff‘s running board. This was then successfully lifted into position and fitted.

This was then successfully lifted into position and fitted. Paul Balshaw commenced the task of jacking up Fluff last Wednesday so that the wheels could be removed and axleboxes examined.

Paul Balshaw commenced the task of jacking up Fluff last Wednesday so that the wheels could be removed and axleboxes examined. Phil Bell is seen moving the wheels once the frames had been jacked high enough.

Phil Bell is seen moving the wheels once the frames had been jacked high enough.

Keith has also been concentrating his time recently in manufacturing new splashers for Wootton Hall.

Keith has also been concentrating his time recently in manufacturing new splashers for Wootton Hall. Disappointingly, the newly acquired regulator quadrant fell at the first hurdle with the end stop coming adrift.

Disappointingly, the newly acquired regulator quadrant fell at the first hurdle with the end stop coming adrift. This has now been successfully repaired and re-fitted.

This has now been successfully repaired and re-fitted. In the meantime we show a photo of Cumbria whilst shunting during its test steaming.

In the meantime we show a photo of Cumbria whilst shunting during its test steaming. More good progress was made with Caliban last Wednesday with Alan tackling the job of scraping in the newly re-metalled bearings.

More good progress was made with Caliban last Wednesday with Alan tackling the job of scraping in the newly re-metalled bearings. With the vision of the locomotive being lowered back on to its wheels in the not too distant future, Ade was checking the spring support pins.

With the vision of the locomotive being lowered back on to its wheels in the not too distant future, Ade was checking the spring support pins. Also achieved last Wednesday, in good time before the lowering of the loco, was the lining out of Caliban‘s wheels.

Also achieved last Wednesday, in good time before the lowering of the loco, was the lining out of Caliban‘s wheels. As forecast in last week’s blog, Ade conducted a shunt which enabled Fluff and FR 20, complete with tender, to be positioned on road three of the heated section of the FRT shed in readiness for the winter work programme. Fortunately it was possible to do the shunt whilst the rain held off and FR 20’s frames made a rare appearance out in the open.

As forecast in last week’s blog, Ade conducted a shunt which enabled Fluff and FR 20, complete with tender, to be positioned on road three of the heated section of the FRT shed in readiness for the winter work programme. Fortunately it was possible to do the shunt whilst the rain held off and FR 20’s frames made a rare appearance out in the open. The new line up in the shed is seen here.

The new line up in the shed is seen here. FR 20’s tender chassis was duly reunited with its wheels last Wednesday although the blustery wind did its damndest to try and make life difficult for us.

FR 20’s tender chassis was duly reunited with its wheels last Wednesday although the blustery wind did its damndest to try and make life difficult for us. However, patience paid off and, after a successful struggle in damp conditions to re-fit the brake gear, the tender was shunted around to the FRT shed late afternoon after Ade had shunted around some more coaches for the RSR.

However, patience paid off and, after a successful struggle in damp conditions to re-fit the brake gear, the tender was shunted around to the FRT shed late afternoon after Ade had shunted around some more coaches for the RSR. We show here a last look at the FRT shed before items are moved around, with FR 20’s boiler (left), Fluff‘s frames (foreground), Caliban (distant left), FR 20’s engine frames and Wootton Hall‘s tender frames (distant right).

We show here a last look at the FRT shed before items are moved around, with FR 20’s boiler (left), Fluff‘s frames (foreground), Caliban (distant left), FR 20’s engine frames and Wootton Hall‘s tender frames (distant right). In the meantime work has continued in rebuilding the platework and assembling other components, with Phil Bell giving the newly fabricated cab sides a coat of red oxide.

In the meantime work has continued in rebuilding the platework and assembling other components, with Phil Bell giving the newly fabricated cab sides a coat of red oxide. Finally, on the sales side, Alison informs us that she now has a brand new badge depicting Caliban for sale. Please contact either Alison or Alan if you would like to purchase one, with a special members’ rate available.

Finally, on the sales side, Alison informs us that she now has a brand new badge depicting Caliban for sale. Please contact either Alison or Alan if you would like to purchase one, with a special members’ rate available. Wednesday saw FR 20’s tender axleboxes being re-assembled and mounted on the journals. This is in readiness for the arrival of a crane this next Wednesday morning when it is planned to place the tender back on its wheels.

Wednesday saw FR 20’s tender axleboxes being re-assembled and mounted on the journals. This is in readiness for the arrival of a crane this next Wednesday morning when it is planned to place the tender back on its wheels. We include a photo this week of Keith silver soldering a flange on to a piece of Wootton Hall‘s injector pipework.

We include a photo this week of Keith silver soldering a flange on to a piece of Wootton Hall‘s injector pipework. Over at Embsay there has been significant progress with Cumbria. A new regulator gland has been cast and machined following the discovery of a fracture in the old regulator gland. This has now been fitted and packed along with a replacement regulator quadrant.

Over at Embsay there has been significant progress with Cumbria. A new regulator gland has been cast and machined following the discovery of a fracture in the old regulator gland. This has now been fitted and packed along with a replacement regulator quadrant.